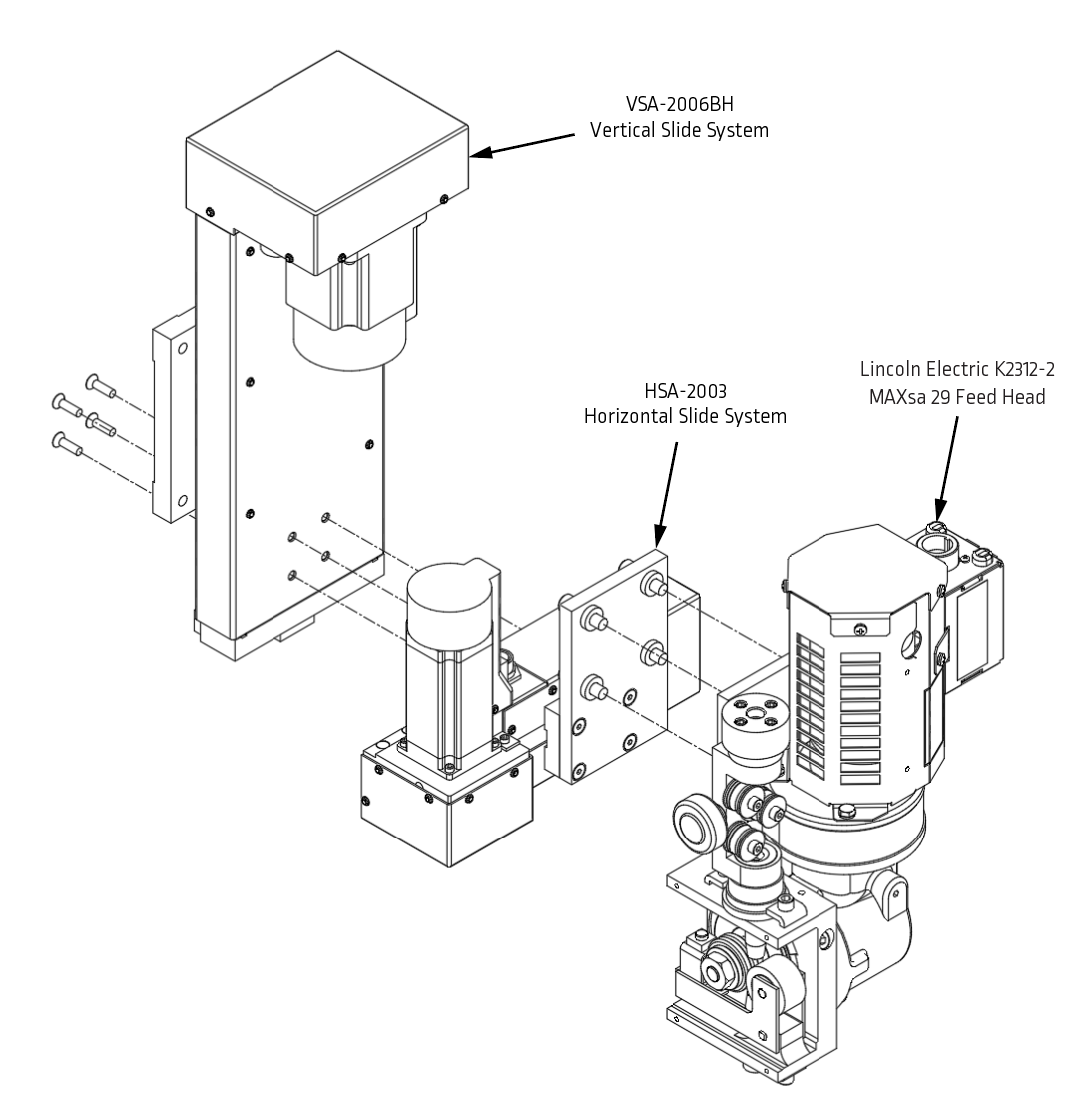

Mechanized Thru-ARC System

Your first step in automation.

MTS is an add-on Thru-ARC™ Tracking System designed to interface to a new or existing welding system and will operate as a standalone tracking system. It only requires the installation of the slides, clamp on current sensor and voltage sense cable with no direct interface to the welding power supply. Connectivity Benefits

The MTS system is supplied in two versions.

Basic system will support the following Thru-Arc™ tracking modes:

- ACC/AVC torch height control

- A=B centerline tracking with torch height control

Adaptive system will support the following Thru-Arc™ tracking modes:

- ACC/AVC torch height control

- A=B centerline tracking with torch height control

- Single side tracking with torch height control

- Width control with constant volume fill

- Inverted A=B centerline tracking with torch height