APEX® 3 and HELIX® M Series equipment

for Mechanized Welding

Innovative technology that’s highly adaptable and easy to operate.

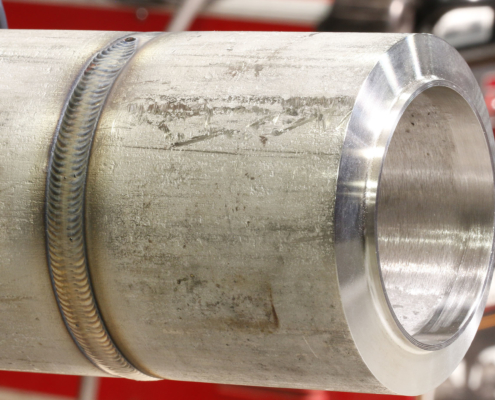

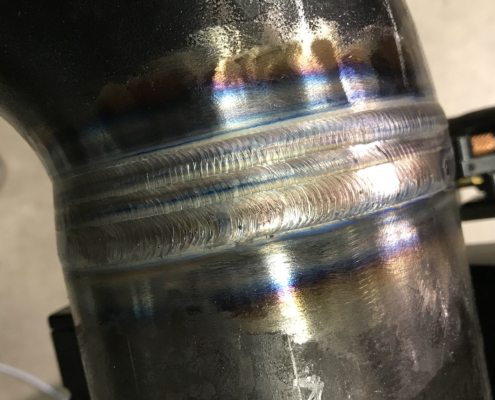

For mission critical orbital welding applications, you can trust the APEX® 3 Series Control Systems from Lincoln Electric. Our APEX 3 Series orbital welding solution establishes one platform for multiple welding processes with quality assurance and extremely precise welding controls for FCAW, GMAW, GTAW and Hot Wire GTAW welding in fixed and out-of-position applications with an ease of use that is second to none.

From Application to Product, How Can We Help You?

Hundreds of companies worldwide trust Lincoln Electric for their orbital MIG and TIG welding applications across multiple industries. That means you can trust us, too.

Complete line of mechanized welding solutions

We have developed a full line of mechanized welding solutions that cover a variety of welding applications. From GMAW or FCAW configured systems all the way to Hot Wire GTAW solutions for both straight track and orbital applications.

Need a system for a specific task?

We can tailor systems to exact customer needs. Please give us a call and we can create a turnkey system based on your exact needs.

APEX® AUTOPILOT

THE FIRST TO MARKET, FULLY AUTOMATED MECHANIZED WELDING TECHNOLOGY

Easily tap into the true benefits of mechanized welding with APEX AutoPilot – Lincoln Electric’s advanced, automated control technology developed for unmatched mechanized performance and ease-of-use. A standard feature in all APEX control systems, APEX AutoPilot features multiple automated capabilities that provide intelligent digital control of the weld process and hardware – helping to reduce operator intervention and maximize start-to-finish weld quality.

APEX® Plug-n-Play, Automated System Configuration & Confirmation

The first step to making a great weld is confirming your system is properly set up and connected. With AutoPilot’s plug-n-play capability, operators can receive automated feedback on system connections – confirming which accessories are properly connected or need attention.

Key Benefits:

- Automatically detects and confirms connection of mechanized components including:

- HELIX M series weld heads and accessories

- APEX 3 series control systems and accessories

- Power Wave power sources and accessories

- Validates welding circuit and polarity are properly connected

- Automatically adjusts pendant control options based on connected equipment

APEX® Auto Sector – Automated Weld Parameter Control

Implementing the correct weld settings can be the difference between success and failure in an application, which is why repeatability from weld to weld is critical. With APEX Auto Sector, operators can reduce the risk of welding with the wrong values at the wrong time by utilizing embedded inclinometer control, allowing the system to automate weld parameters based on preprogrammed settings for a specific section of the weld sequence.

Key Benefits:

- Automates parameter control and can change any aspect of the welding process on the fly

- Settings automatically ramp and adjust between predetermined sectors for seamless transitions

- Works for double up, double downs, and 360 degree welding with up to 1 degree of resolution

- Reduces operator fatigue and risk of missing a setting at a critical time in the weld sequence

APEX® Auto Height – Automated Weld Head Height Control

Designed to simplify process set and reduce operator error, AutoPilot’s Auto Height capability provides automatic adjustments to torch height for multiple process applications. So whether you’re running MIG or TIG, Auto Height control automatically adjusts the torch height based on the set amperage (MIG) or voltage (TIG) parameters – helping to improve heat input control and maximize weld quality.

Key Benefits:

- Improves tracking and control when transiting across dramatic changes in surface distances

- Prevents over shooting when minor offsets are detected

- No external sensors needed

- Dials in the ideal height for improved heat input control and improved operator ease-of-use

APEX® Auto Path – Automated Weld Pass Recording and Playback

Improve jobsite efficiency and overall productivity on large, multi-pass welds with AutoPilot’s Auto Steer capability. Designed to decrease operator interaction during long welds, Auto Path allows operators to record weld head adjustments during a first pass and then initiate playback capabilities on the following weld pass – automatically adjusting the weld head to follow the same initial path. In return, this frees up operators to run multiple systems at once or attend to other pre or post weld needs.

Key Details

- Easily initiate welds on multi-pass applications by recording weld head path adjustments and play back the weld path for subsequent passes

- Can play back the recorded track in either forward or reverse directions for improved efficiency

- Automatically stops welding process when the system detects issues, such as running out of wire

- Automatically senses and stops welding process when head reaches the end of the track

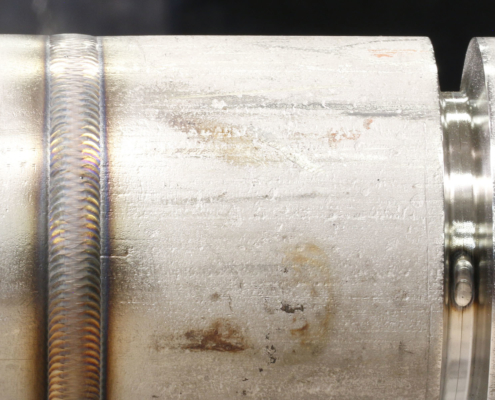

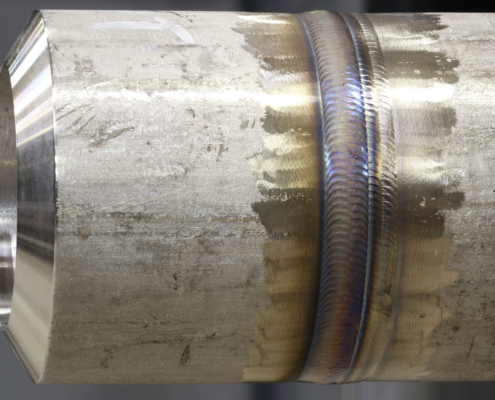

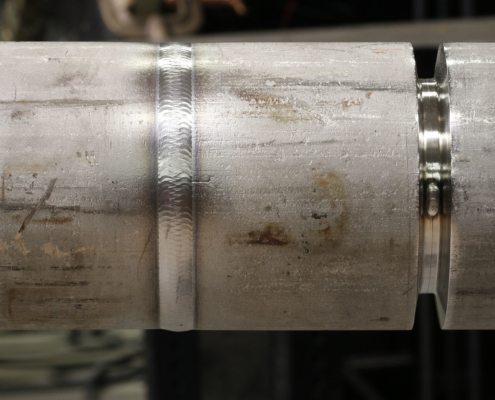

HELIX® M Series Weld Heads: Your Portable Welding Solution

The HELIX® M series is the next generation in weld heads for mechanized welding. Based on a digital platform, the HELIX M Weld Heads feature plug and play connectivity capable of a variety of welding solutions. From small bore pipe and tube to large bore pipeline, vessels and structural welding, we have you covered.

APEX® 3 Series Controllers: A Welding System with a Superiority Complex

From construction to process piping, your orbital welds are subject to an exceptionally high standard of quality and productivity. Calibration at the front end of the process can be challenging and time consuming. Our APEX® 3 series welding system built on the Power Wave® technology meets the challenge. Our intuitive, lightweight pendant offers a large color screen, and easy to navigate buttons and switches which help to provide our customers the lowest learning curve in the industry.